In this Expert Q&A, we spent some time in the James Heal lab, speaking with Technical Specialist, Peter Goodwin.

We discuss what 'durability' means, how we define it, and how we can test for it. This is crucial in an industry that is increasingly competitive for retailers and brand owners, with the rise of 'fast fashion' and the need for quality testing to support diverse performance and commercial requirements.

Understanding and improving the durability of textiles is crucial for textile scientists, technologists, engineers and those designing, testing and manufacturing textiles - yet, 'durability', although a simple word to use, is often a hard concept to define, explains Peter:

Textile items undergo a wide range of challenges related to their use and care, and can fail (and thus lack durability) in many ways. The fault may lie with the item or the way it is used or the way it is washed and dried. In order to minimise unexpected failures, laboratory testing plays a key role. Laboratory tests, carefully developed and maintained, mimic conditions of use - and careful interpretation of results can provide valuable insights for the manufacturer and retailer.

Peter Goodwin, Technical Specialist - James HealThe ability of a fabric to resist wear is an essential aspect of its performance.

Can you explain what durability testing is?

A dictionary defines 'durable' as 'able to exist for a long time without significant deterioration', and this therefore, is the basis of the property that we know as 'durability'.

Yet, there's a point for discussion here. Casual dressing is more prevalent than ever before; and popular 'fast fashion' may dictate that garments are not required to exist for a long time.

So, we may have to contemplate two different kinds of product:

- those that are designed to last for a long time, formalwear or workwear, for example;

- and, those that are designed to be 'fit for purpose', often garments of a more casual nature.

Thus different performance requirements are required for products in different sectors of the market. But this isn't the complete story either...

If a consumer pays £5 for a T-shirt, do they expect to receive a lower quality, less durable garment than someone who pays £45 for a similar but branded T-shirt, for example?

Whichever is the case, there has to be a testing regime that ensures that the fabric or garment properties are suitable for the market sector in which they will be sold.

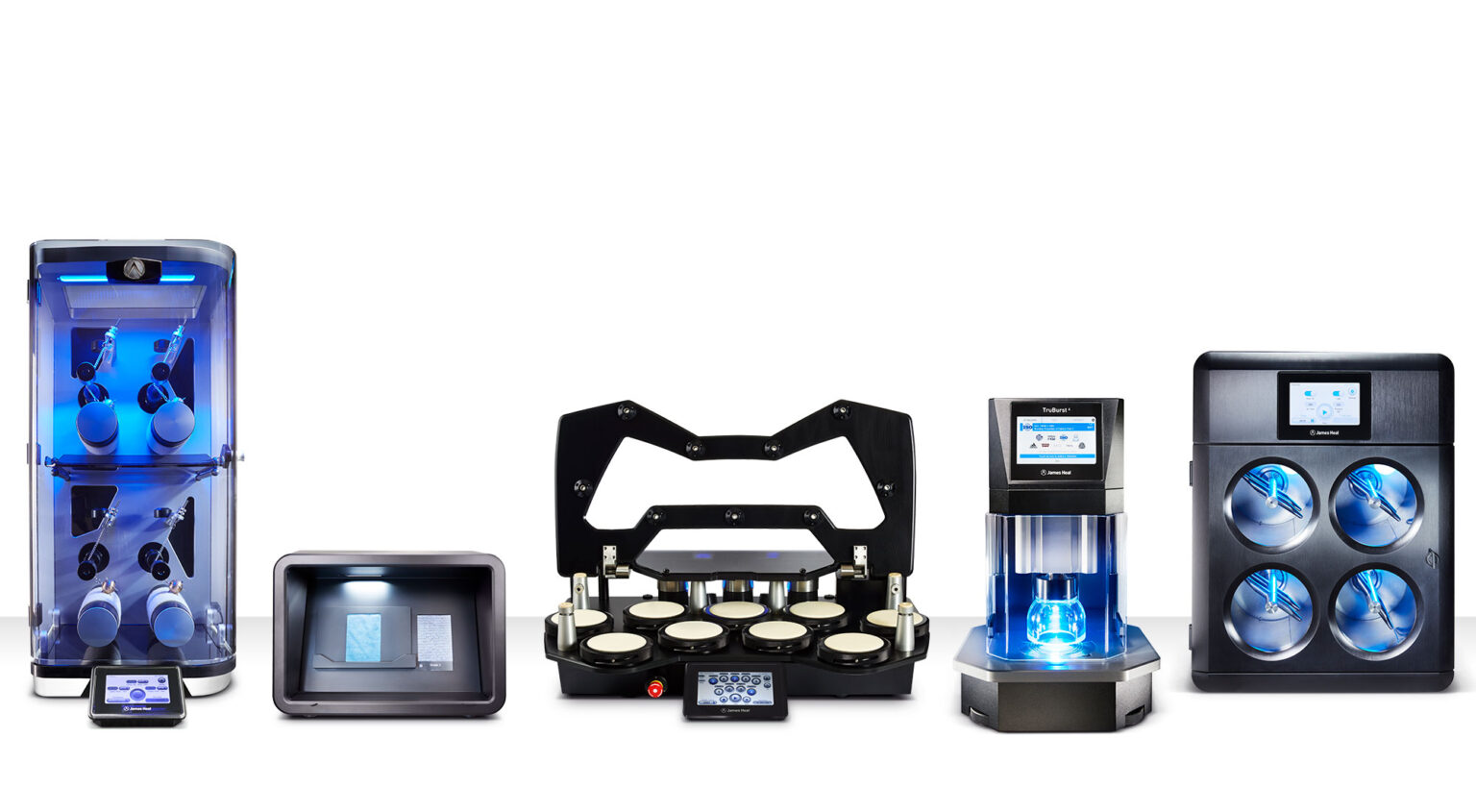

This regime must be based on widely accepted and standardised test methods. It must also utilise controlled conditions and accurate, calibrated instruments. Over the years, James Heal has worked to support the industry by providing products and services that meet these requirements.

Equally the Test Materials used to perform the tests must be correct and consistent. All of James Heal's Test Materials are rigorously specified and tested so you can have complete confidence that they will receive a consistent product that will always conform to the relevant specifications.

Peter Goodwin, Technical Specialist - James HealJames Heal produces high quality instruments, service, calibration and test materials; if users are trained to carry out the tests correctly and assess the results consistently, they will produce the vitally needed, accurate and correlateable results.

So what aspects of the garments are tested for their durability?

Alice: Simply the aspects of the garment that will make their appearance or performance unacceptable to the wearer.

Three categories of property should be evaluated:

- Durability of colour - amongst other properties, colour change during laundering, colour change or staining due to water or perspiration solutions, staining of contrasting parts of the garment during laundering or wear, fastness to crocking and colour change due to exposure to light;

- Physical durability - tensile and tear strength, seam performance, elongation and recovery, bursting strength, resistance to abrasion, propensity to form pills and snags, change in garment size when laundering, change of handfeel following washing, stain release performance and so forth;

- Visual appearance - durability of 'wrinkle-free' finishes and 'easy to iron' finishes, assessment of surface disturbance following wear and repeated laundering, seam puckering and shape retention etc.

What are the typical finishes that are tested for durability to washing?

Those which are applied to fabrics or garments which, when incorrectly applied, or when an incorrect choice of chemicals has been made have an adverse affect on the ongoing performance of the finish.

Typical examples of such finishes are wrinkle-free and easy to iron finishes, anti-pill, stain release and flame retardant finishes. Repeated laundering of all of these finishes can have a deterious effect.

Testing all of these finishes is equally important for small and large producers and this is where the choice of testing instruments is so important.

James Heal's Impulse Random Tumble Pilling Tester is ideal for testing anti-pill finishes using the ASTM D3512 Test Method.

This instrument, with its single test container, is ideal for the small producer whilst the ability to connect up to four, independently operated units together, from single air and electrical supplies, is the most cost-effective and efficient solution for the large volume producer.

With an increase in rapid prototyping and direct-to-garment printing, a number of tests can be performed in the DynaWash Duo, including print durability, pleat retention, cockling, flock retention, crinkling, differential shrinkage and security of attachments, plus many others.

This is particularly useful for laboratories performing a high volume of repeated wash tests.

What type of testing do you consider to be durability testing?

That which clearly highlights the possibility of serious customer complaint if the garment fails to meet the relevant specification.

An example of critical testing is Abrasion Testing. James Heal's Martindale range of highly specified instruments are designed to be easy to operate - a feature of all our instruments - so little training is required for your operators, saving time and costs.

Another example is that of testing a fabric's potential for snagging. In many synthetic blend products the ease with which unsightly snags, or loops of thread, can be pulled out of the construction can be a major source of consumer dissatisfaction."

Buyers and Test Houses, together with James Heal, developed an instrument, test method, assessment procedure and instrument called Snagpod.

This package work has been widely acclaimed by many as having produced a snagging test that much more closely represents what happens to a product in 'real life', than does any other existing testing protocol.

Buyers and testing houses, together with James Heal, developed an instrument, test method, assessment procedure and instrument called Snagpod. This package work has been widely acclaimed by many as having produced a snagging test that much more closely represents what happens to a product in 'real life', than does any other existing testing protocol.

In your opinion are most tests applicable to fabrics and to garments?

Yes, if testing is carried out at critical points during the fabric production process then it is possible to predict the performance of the end-product.

We believe that testing fabric during and after production allows the supply chain to become more efficient. If fabrics and processes are developed to be technically correct, then process, or quality control testing will predict that the garment will meet the pre-agreed specification.

Quality assurance testing of the finished garment then gives the buyer the confidence that the products that go into his stores will meet his requirements and will support his position in the market-place.

Of course, some tests are better carried out on fabrics than on garments. For example tests such as Light Fastness on TruFade are most suitable for fabric testing.

Light fastness tests relate specifically to dyestuff choice, not dyestuff application; so it's critical that any problems associated with this phenomena are highlighted at the earliest stage in a garments development. If light fastness testing is carried out only at the end of the process the failure is very costly in terms of the money spent to produce the failed product. It may also have a serious effect on the buyer who may have to withdraw the product at a very late stage.

Are there are specific types of garments that may be viewed differently?

Workwear and industrial wear products such as uniforms, overalls, protective clothing and those with high visibility safety panels often fall into a different category. These products are often subjected to much harsher use and more searching environments during their lifecycle, and have separate standard that apply in some cases.

Military uniforms fall into this category and these may be seen as the most extreme examples of the need for accurate and correlateable durability testing. Literally, lives may depend on the performance of the product. This again totally supports the James Heal philosophy - that the need for accuracy is vital.

Often the lifecycle is also expected to be longer than for a fashion or formal piece of domestic apparel. In many cases, they are laundered on contract, not domestically; and it is therefore critical that the garment is developed and designed such that these more difficult performance criteria are accommodated in the product specification.

Final thoughts

Accurate test results that come from tightly specified regularly serviced and calibrated machines, quality assured Test Materials and well trained technicians and they are critical for an industry that supports such diverse performance and commercial requirements. Our philosophy is always to maximise its support for the supply chain by providing the highest standards possible in everything it offers, and by this, to provide the greatest benefit for all of the companies and organisations that it works with.

If you have further questions or need advice and guidance on materials testing, contact us for support.

Peter Goodwin, Technical Specialist - James HealOur Technical Team offer applications support to customers around the world, and are also responsible for quality control of our test materials. We help with the product development process; checking to see if our products comply with relevant standards,evaluating them from the user perspective.

We work with instrument prototypes to ensure they meet our customer's needs, and we also sit on standards committees to guide the creation and revision of standards. We offer our expertise on testing as technologists, but also on how the instruments that do the testing work.