Stringent testing for the most extreme conditions

As a military wear manufacturer, we understand that your efforts are concentrated on increasing performance and safety, whilst making quality and comfort a priority.

The typical tests performed on military grade materials and uniforms include:

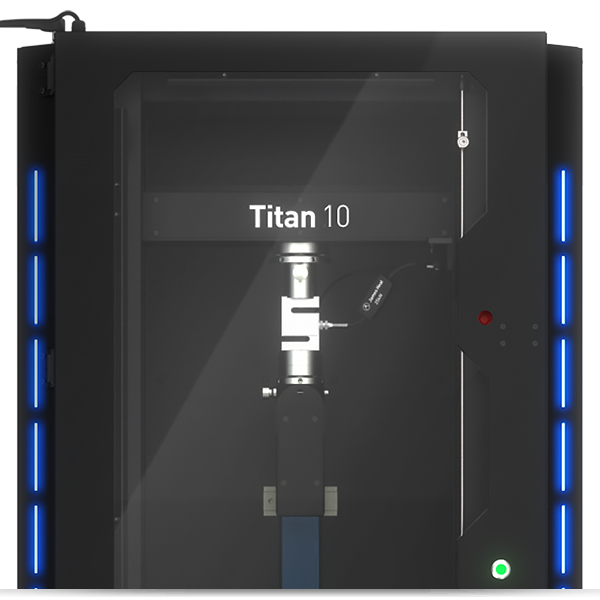

- flame resistance

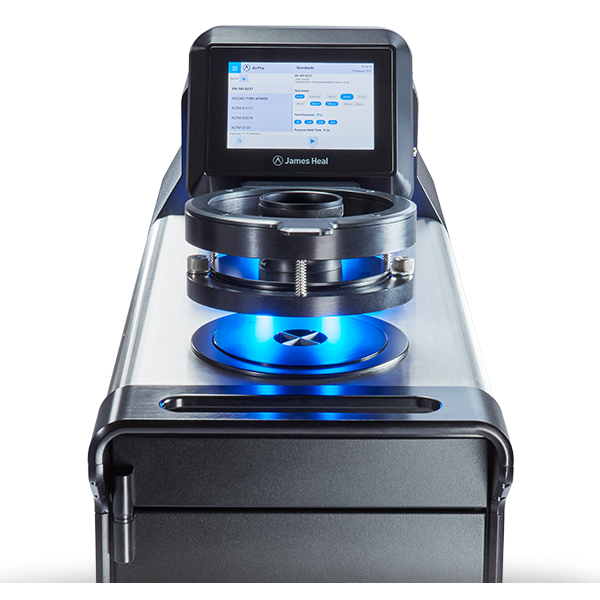

- air permeability

- thermal resistance

- burst resistance

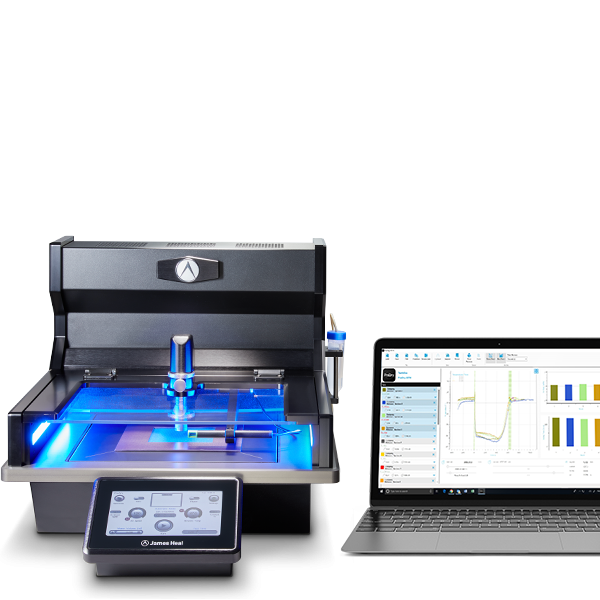

- sweat wicking

- water repellency.

Comfort and performance put to the test

Testing and quality control ensures a high level of product quality with consistent results and performance.

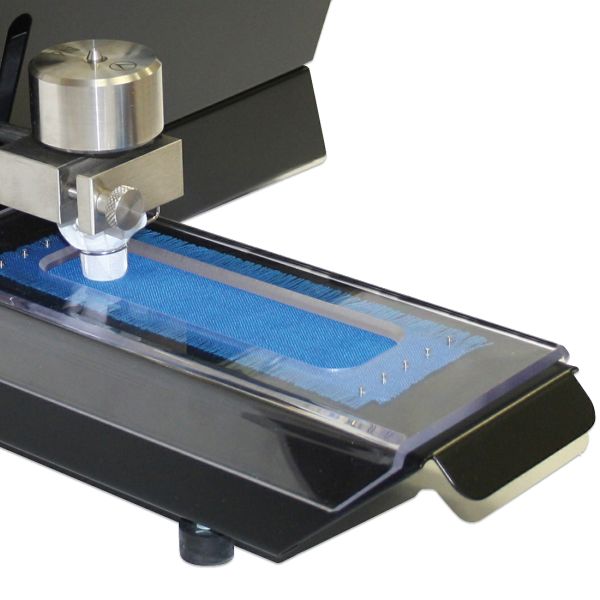

Performance and comfort are crucial here: we've seen increased demand for testing to assess water vapour transmission, drying rate and sweat wicking for these types of materials - along with the more common tests for flammability and colour fastness.

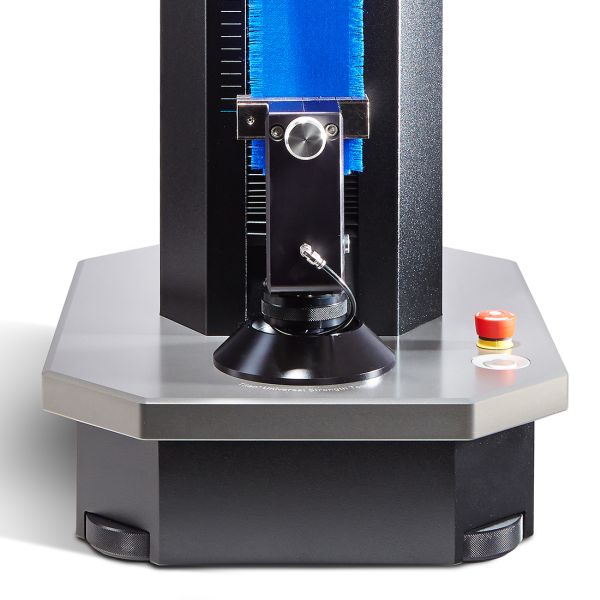

Accurate, reliable, repeatable results - every time

Textile materials that are used in military wear must be able to cope with the most extreme requirements, to ensure product quality, safety and functionality to protect the wearer.

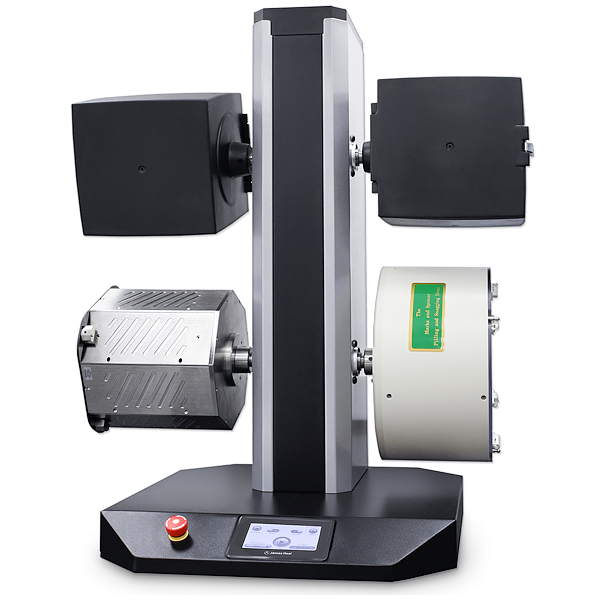

Since 1872 we've been on a mission to improve every aspect of materials testing, so our customers can achieve consistent and accurate results, every time.

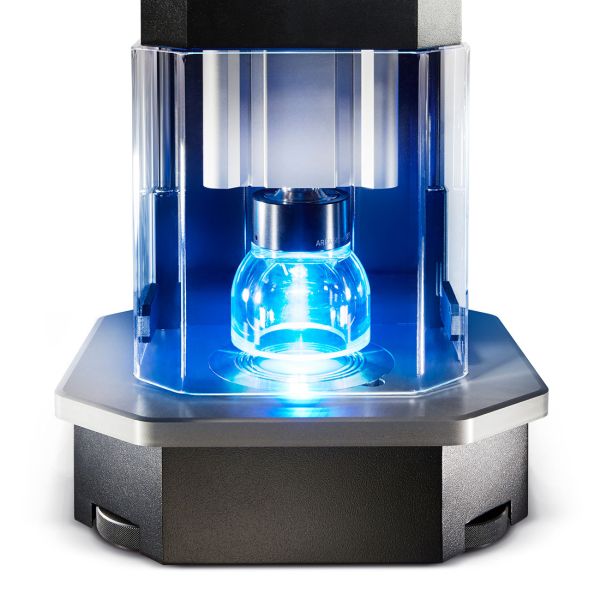

Our new Performance Testing Range has been designed for testing performance wear and technical textiles.