In our latest industry insight, we’re focusing on testing safety footwear.

What’s covered:

- An overview of safety footwear testing

- Why test safety footwear?

- How To Assess Footwear Efficacy: Types of Tests Conducted

- Comfort testing

- Safety testing

- Performance testing

- Choosing appropriate testing instrumentation for safety footwear

- Final thoughts

Overview of safety footwear testing

The safety of workers is of utmost importance in any workplace environment, and this includes ensuring that they are equipped with the appropriate personal protective equipment (PPE). One crucial component of PPE for workers who spend time on their feet in hazardous environments is safety footwear, also known as safety shoes. These specialised shoes are designed to protect the feet from various workplace hazards such as falling objects, sharp objects, electrical hazards, slippery surfaces, and in some cases extreme temperatures and fire.

In this article, we will discuss the importance of testing safety footwear and the various types of tests used to ensure their effectiveness.

Why test safety footwear?

“Safety footwear is designed to provide protection to the feet in various hazardous situations, but it is essential to ensure that these shoes are effective in doing so”, begins Peter Goodwin, Technical Specialist at James Heal. Peter continues, “Testing safety footwear is necessary to determine whether the shoes meet the required safety standards and specifications and can withstand various workplace hazards”.

What does testing help to identify? Here are some of the areas commonly evaluated in testing:

- Compliance with safety standards: Safety footwear must comply with specific safety standards such as EN, ISO, ASTM, OSHA, or ANSI. Testing ensures that the footwear meets these standards and can provide adequate protection. These standards may specify minimum requirements for factors such as impact resistance, compression resistance, puncture resistance and slip resistance.

- Defects and weaknesses: Testing can identify defects and weaknesses in the design or construction of the safety footwear. This information can help manufacturers to improve their products and ensure that they provide maximum protection.

- Durability: Safety footwear is expected to last for a specific period, and testing can help determine this period with the durability of the shoes. This information can be useful for workers and employers to make informed decisions on when to replace worn-out safety footwear.

How to assess footwear efficacy: Types of tests conducted:

In order to ensure that safety shoes meet certain standards for comfort, safety, and performance, they undergo rigorous testing to evaluate and determine the criteria listed above. These tests can include compression resistance, impact resistance, electrical hazard resistance, and slip resistance tests, which we explain further below.

Comfort testing

Comfort testing is typically conducted by a panel of testers who wear the shoes for an extended period of time and provide feedback on the fit, feel, and overall comfort of the shoes. Testers may rate the shoes based on factors such as cushioning, arch support, and breathability.

Safety testing

Safety testing involves subjecting the shoes to various hazards that they may encounter in the workplace, such as impact, compression, puncture, and electrical hazards, explains Peter: “For example, shoes may be tested by dropping a heavy weight on them to simulate an impact or by applying pressure to the toe area to test their compression resistance. Shoes may also be tested for their slip resistance and their ability to provide protection against heat, cold, and chemicals”.

- Compression Resistance Test: This test measures the ability of the safety footwear to withstand a specific amount of compression force, simulating the impact of heavy objects falling on the foot. The test involves compressing the toe area of the shoe with a specific amount of force (e.g.15 kN) and measuring the amount of deflection that occurs.

- Impact Resistance Test: This test measures the ability of the safety footwear to protect the foot from heavy falling objects. The shoe is dropped from a specific height onto an impact test device, and the amount of force transmitted to the foot is measured.

- Electrical Hazard Resistance Test: This test measures the ability of the safety footwear to protect the wearer from electrical shocks. The shoe is immersed in water and subjected to an electrical current, and the amount of current that passes through the shoe is measured.

- Slip Resistance Test: This test measures the ability of the safety footwear to prevent slips and falls. The shoe is tested on a surface with a specific level of slipperiness, and the amount of friction that the shoe provides is measured.

Performance testing

Performance testing involves evaluating the durability and quality of the shoes. Shoes may be tested for their resistance to abrasion, tearing, and flexing. They may also be tested for their ability to withstand exposure to water, oil, and other substances commonly found in the workplace.

Choosing appropriate testing instrumentation for safety footwear

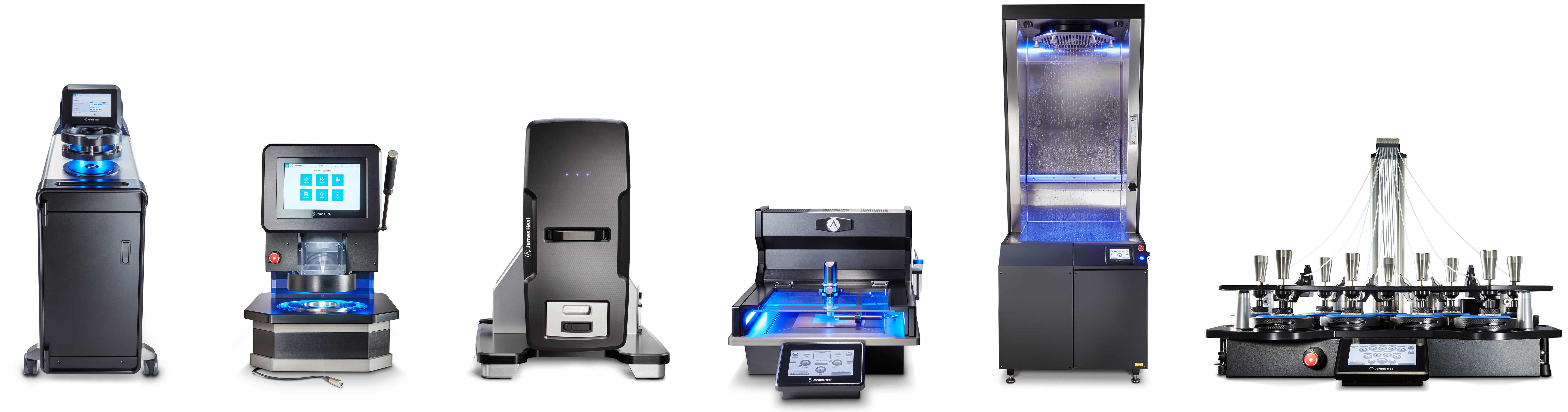

Testing is a crucial step in order to meet the relevant standards for safety footwear functionality and performance. James Heal test instruments are suitable for many of these, such as:

- Air permeability

- Flammability

- Colour fastness

- Perspiration and crocking

- Compression

- Attachment strength

- Abrasion resistance - standard wear and abrasion test

- Wet abrasion

- Tear strength

- Burst strength

- Water resistance and water repellency

- Wicking

Learn more about the James Heal performance testing range.

Final thoughts

“Overall, safety shoes and protective footwear are tested for comfort, safety, and performance through a combination of hands-on testing and industry standards,” says Peter, who adds that by meeting these requirements, employers provision of safety footwear helps protect workers from work environment hazards, and provides employees with the comfort and durability they need to do their jobs safely and effectively.

Additional resources

Want to learn more? Access our free Lab Manager’s Guide to Protective Wear Testing

For further reading visit our News & Insights section for case studies, articles, expert interviews and more.