In this latest Applications Insight, we are focusing on wicking testing and grading, which includes links to the brand new AATCC TM217-2025 method, developed by the James Heal team.

What's covered:

- An overview of wicking

- The science behind wicking behaviour

- Fibres preferred for moisture management

- The role of wearer comfort and wicking

- Tests for wicking (including the new (AATCC TM217-2025)

- Traditional methods for measuring wicking

- Introducing the WickView advanced imaging system

- Grading the 'true wicking' area

An overview of wicking

Wicking is the transference and management of liquid moisture in or on a textile or garment. The official definition of wicking action is "the process of a liquid flowing in a narrow space without the assistance of, or even in opposition to, any external forces like gravity". The effect can be seen in the drawing up of liquids between the hairs of a paint-brush, in a thin tube, in porous materials such as paper and plaster, in some non-porous materials such as sand and in liquefied carbon fibre.

In our case, when an athlete sweats, we would expect that in a high performance garment the liquid would disperse relatively quickly through the fabric, and not gather the moisture in one place. The liquid moisture from perspiration will be drawn up through the capillary design, usually in the warp or weft, or more likely the ‘course and wales’ of knitted fabrics, to take the moisture away from the point of origin, and eventually it will evaporate or run off.

The way we test wicking has changed significantly, though many traditionally basic methods are still used in determining the effectiveness of a fabrics propensity to wicking. Read the full article to discover the latest innovations in wicking technology and grading, and why the new AATCC TM217-2025 wicking standard gives the most comprehensive view of wicking testing to date.

Lisa Keeling, Technical Specialist"Fabrics and garments are designed from the yarn up to have wicking properties, with many production stages contributing to the effectiveness of the fabric or garment as a whole."

The science of wicking behaviour

In this area of performance testing, there are a number of definitions:

- Hydrophobic – the repulsion of water from entering the structure

- Hydrophillic – the tendency to mix with, dissolve in or be wetted by

- Oleophobic – the same as hydrophobic, only with oil instead of water

- Oleophilic – the same as hydrophilic only with oil instead of water

When a fabric or textile is described as ‘hydrophobic’, this means the material is repelling water through a lack of mixing and absorption of water.

In contrast, ‘hydrophilic’ textiles allow water to mix, dissolve into or be wetted easily.

The same can be said for ‘oleophobic’ and ‘oleophilic’ textiles, which have the same meanings, however instead of water it is oil that would be present.

For wicking, what we want is a textile that can effectively transport the moisture away its point of origin.

In conjunction with the fibres used in a fabric, the fabric construction also plays a critical role in the effectiveness that a textile has at wicking. As per the AATCC definition, wicking is the movement of a liquid, by capillary action, along or through a material. This liquid is often liquid perspiration (sweat) as moisture wicking fabrics are considered an important element of modern sportswear and outdoor-wear.

Lisa Keeling, Technical Specialist"A common misconception is that cotton fibre gives us fabrics with effective wicking, but this is not the case. Cotton is a highly absorbent fibre which stays wet and takes a long time to dry, thus being the exact opposite of what is needed for effective wicking. "

Fibres preferred for moisture management

Good wicking fabrics that have contact with the skin should always have low moisture regain, and they should spread and transport liquid moisture along its structure. These include polyester for its low moisture absorption, polypropylene for its excellent moisture wicking, and polyamide for wicking and durability properties.

A common misconception is that cotton fibre gives us fabrics with effective wicking, but this is not the case. Cotton is a highly absorbent fibre which stays wet and takes a long time to dry, thus being the exact opposite of what is needed for effective wicking.

Fabrics with fine fibres and yarns that have substantial spaces in-between are often effective at wicking as the construction aides the capillary action needed for the transportation of moisture. Fabrics can also be treated or finished afterwards to have wicking properties added, which can also be very effective.

Moisture loss statistics below gathered by the Hohenstein institute in Bangladesh, detail different rates of moisture loss during a range of sporting activities, which all required special performance wear for the activity.

Some examples of typically good wicking which we would expect to see in sportswear fabrics (with moisture loss in litres) during these activities include:

- 100 metre sprint 0.1

- 90 min tennis 2.0

- 90 min football 3.0

- Marathon 4.6

- Triathlon 20.0

The role of wearer comfort and wicking

Wicking is directly related to comfort, as good wicking means the textile or garment will allow the garment to effectively manage moisture produced by perspiration. The two go hand in hand, with effective wicking equalling a more comfortable and favourable exercise garment.

Lisa Keeling, Technical Specialist“Temperature control; to cool, the body sweats, keeping us

at a regulated 36.5 – 37.5°C . A textile garment can either help or

obstruct sweat evaporating, directly linking it to comfort.”

Moisture management is of extreme importance for any high-performance apparel and is understood to be the ability of a textile to absorb gaseous or liquid humidity from the skin, transport it through the textile to outer surface, and then release it into the surrounding air.

The transfer of perspiration from the skin to the atmosphere regulates the body temperature and maintains heat balance thus controlling the comfort level of environmental conditions and activity.

Clothing plays an important role in eliminating extra heat produced, to keep the body at a core temperature of 37°C and is an important factor in optimising comfort and maximising performance. The role of moisture-management fabrics is to regulate heat and moisture to maintain a constant body temperature. Wetting and wicking take place before perspiration evaporates from the skin through the fabric into the atmosphere.

Effective wicking for performance wear worn in cold temperature conditions such as hiking in snowy and icy environments, is imperative. Poor wicking would mean that when the wearer perspires, the liquid sweat will be concentrated to one area in the garment, creating a much wetter area than should be acceptable. With exposure to the cold atmosphere, the wearer can then experience a rapid drop in skin temperature, which leads to what is often referred to as 'post-exercise chill sensation'.

Tests for wicking

Testing for moisture management properties include two main types:

- Tests for absorption and wicking of liquid moisture within a fabric, and;

- Tests for rate of drying which is the evaporation of liquid moisture from a fabric

Starting with the base layer there are a number of different properties and different ways these can all be tested. Moisture management and wicking properties can be tested by a number of standard methods which are mainly AATCC methods and these aim to measure the ability of the fabric to transport moisture through its structure. Several AATCC methods for drying rate also exist which all involve timing how long a wetted fabric takes to dry by a number of different drying methods such as heated plate.

Other base layer performance testing types include:

Most common tests for wicking:

Test standards for wicking have up to now been considered quite basic, predominantly due to the grading and the variability when testing the specimens, with AATCC 197 and AATCC 198 being the universal marker for most wicking testing, however that has changed with the recent publication of a brand new standard, developed from the team at James Heal.

In June 2025, AATCC released the brand new 'Moisture Management Method' , entitled Liquid Moisture Management: Vertical and Horizontal Wicking — Image Analysis. This test method is game changing in both the testing and gathering of test results for assessing the moisture management properties of high performing fabrics and garments.

The new method of wicking testing devised by James Heal using WickView, rules out many of the variable issues traditionally attributed to wicking tests.

Traditional methods for measuring wicking

The vertical wicking of textiles is a very traditional method of wicking test, which aims to measure the ability of a textile to transport liquid moisture vertically through a prepared specimen.

This is a basic way of testing the wicking capabilities, and it does have some downsides, such as:

- Difficult to see wet edge, especially on dark fabrics

- Inability to determine transfer through the specimen

- Wicking rates (calculated for a circles specifically) are overestimates, and we can’t pinpoint specific measurements

- Rate of water dispensing is variable

Horizontal wicking tests, also known as the ‘droplet test’, is also another traditional way of testing for the wicking efficiency of a textile.

Instead of the specimen drawing water vertically, a small continuous flow of water is applied manually (which is the traditional way) to the flat horizontal surface, and the increasing area, or spread of the water, is measured. The area being recorded is usually done so with a digital camera, in increments and at certain points in time throughout the process.

Introducing the WickView advanced imaging system

A key measurement captured by WickView to determine the comfort levels that will be experienced by the wearer is the transportation of moisture from the skin side to the face side of the fabric.

Advanced imaging technology

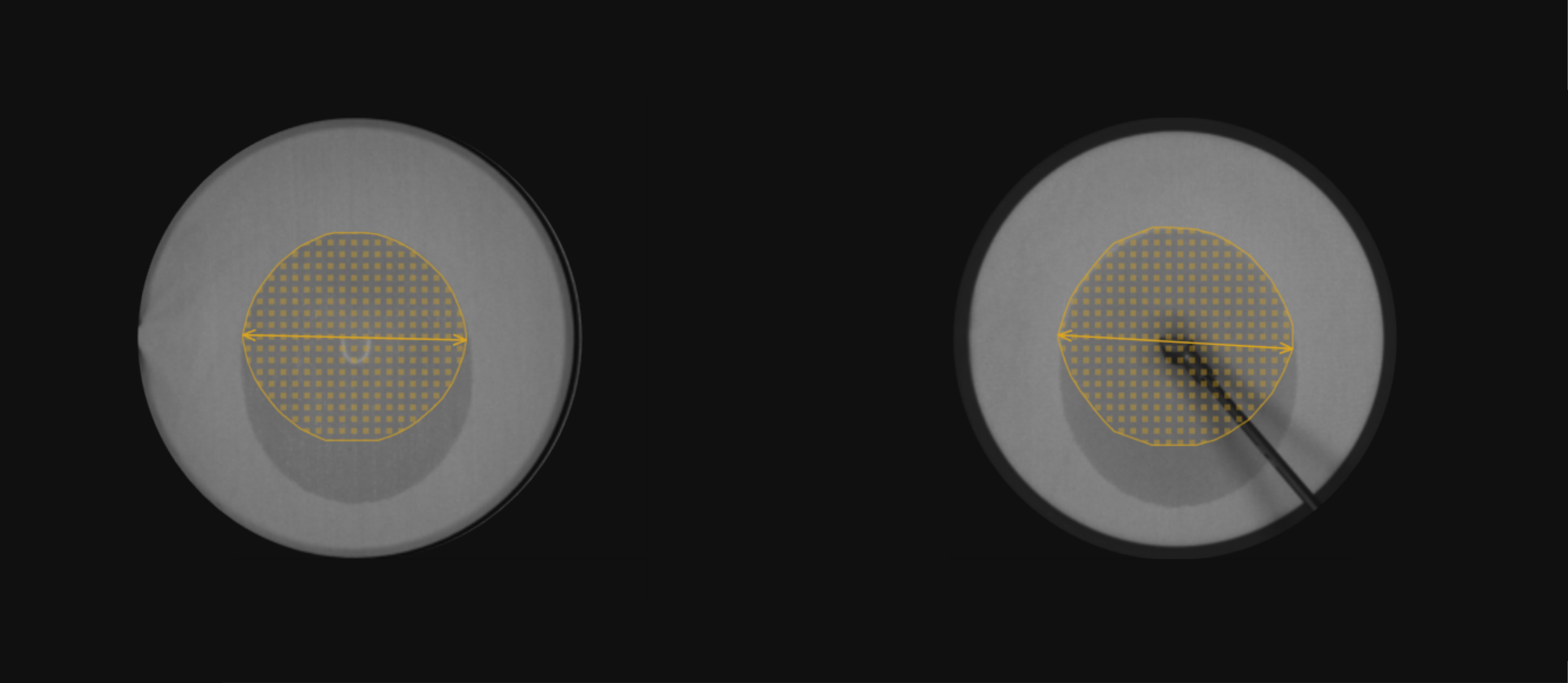

The use of advanced imaging technology also increases accuracy by measuring the true area boundary and the wetted-out area of the textile. We know the human eye cannot accurately detect moisture on dark and patterned materials, which is why WickView uses infra-red, UV and natural light to automatically capture and identify moisture movement and behaviour pattern, enabling the 'true wicking' value of a fabric to be measured.

Intuitive TestWise software

TestWise software within WickView enables the capture of two images per second in a live video recording, which the user can pause, rewind and capture multiple pieces of data in a clear format including graphs, video and data output. This is especially useful in presenting technical findings to colleagues and partners in different locations, and to a non-technical audience given the range of data and results that are available.

TestWise also enables the user to adjust vital parameters such as dosing volume and speed making it easier to categorise textiles across a range of performance applications.

Advanced assessment

This type of advanced measurement and assessment for wicking has not existed until now, but with the rise of ultra-high performance wear in particular, this level of detail in wicking testing and measurement is increasing in demand.

Lisa Keeling, Technical Specialist"Traditional tests for wicking use a small number of data points and is more one dimensional. The new AATCC test method using James Heal's WickView collects a wider range of data points and uses them to create an overall wicking grade for a fabric. This is even more powerful when evaluated in conjunction with drying rate testing to AATCC 201 to get the best insights into a fabric's moisture management capabilities."

Grading the 'true wicking' area

For grading the wicking of a textile on horizontal tests, the method of gathering the data contributes significantly, with a lot of current methods using basic distance and time as a measure, and in only singular directions or in general area measurements, which often include areas or sections that have not proven to wick liquid moisture away. The final wicking results are often given from areas that are not 'true' to the actual multi-directional spread of the wicking area after dosing.

The new, precise way to grade wicking specimens

Given the variables involved between different yarns, fibres, fabrics and fabric constructions, whether vertically tested or horizontally, tests previously have not been able to provide an accurate report of how a specimen will behave with basic systems of measuring a wicking spread. James Heal developed a new way to grade wicking specimens that covers a much more precise and accurate representation of a ‘true wicking’ area, to give in-depth results that would be comparable in both horizontal, and vertical testing.

New testing method and grading system

The newly released AATCC test method developed in conjunction with James Heal, ensures accurate testing with the addition of being able to view and share data and real-time video footage of the test process. Integrated cameras mounted on either side of the specimen within WickView uniquely track, record and measure the multi-directional movement of moisture through a fabric on both the skin and face sides. A number of parameters can be measured which can be used comparatively with other tests, including identifying and discounting aspects such as gravitational pull and run-off, which can often skew results.

The test method was developed with AATCC and James Heal Technical Specialist Lisa Keeling, and details the method for testing horizontal and vertical testing on WickView, which also includes how to grade the different data points gathered during the test.

Why the new system is needed

Traditional tests for wicking use a small number of data points. The AATCC test method collects a wider range of data points and uses them to create an overall wicking grade.

WickView software gathers 16 data points from either a horizontal or vertical test, which given the flexibility of being able to perform both tests on this instrument, means that we are able to draw comparisons between each 16 data points or combine, to build up an even better picture of the wicking behaviour for the specimen being tested.

Contact us to request a live online demo with our Technical team!

Enjoyed this article?

We'll be sharing more testing insights and application articles on our 'News & Insights' page - check out our social media and website for updates.

For related content, see...Applications Insight: Dry Rate Testing

Contact us today

Get support from the textiles testing experts and talk to us about your testing requirements.