In this latest instalment of our Meet the Expert interviews we spoke to Neil Pryke, Group Managing Director for the PPT Group.

He reflects his career as he celebrates 25 years with James Heal, highlights key milestones, and hints at what the future holds...

In the early days

As a child I was fascinated by how things work, I took apart my bell and hammer alarm clock, made my own go-karts and loved to build Lego.

At 16 I decided to go straight into working and got my first job as an apprentice technician at Avery Denison. Avery Denison was based in Leeds, West Yorkshire, and whilst there I designed tensile and compression testing machines.

I originally used a drawing board as personal computers were rare. My first CAD PC had a 286 processor! My last position at Avery Denison was the Principal Mechanical Engineer where I managed two small teams.

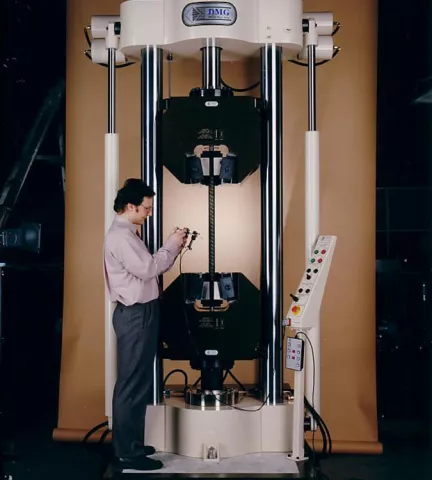

My final project was a 2,000 kN Universal Testing Machine for the Turkish Standards Institute which had four columns and stood 6.6 meters tall, obviously very different in scale to Titan.

When did you start working for James Heal?

I spotted a half page job advert for a Senior Mechanical Design Engineer at James Heal in the local paper and after three very long interviews I finally got the job.

I was interviewed by the Technical Director and David Repper, the MD and owner at the time. The interviews were very intense, during one interview, I was shut in the boardroom with an old Elmendorf tear tester and was tasked with recommending a product re-design.

David called his interview technique 'peeling the onion' and I felt very peeled by the end of it! I joined James Heal on my birthday in July 1997 at age 29 and my plan was to stay for two years to gain experience.

So why did you stay?

James Heal decided they wanted to design a new tensile tester and install 3D CAD for the first time. I had the necessary skills and experience that the company was looking for. I was the project team leader and the senior mechanical design engineer and two years after I joined James Heal, we showcased the Titan at ITMA Paris 1999 and received an amazing response.

How did your role evolve during your time at James Heal?

As the Titan was such a success, I decided to ask for a shot at a role which had come available, Production Manager. I was ambitious to learn new skills and advance my career. Fortunately, I must have impressed the boss as I got the job and was thrown into the deep end very quickly; the role was very fast paced. In contrast to my previous role, I realised that I had to absorb a lot of information quickly and learn from it, all whilst managing a much bigger team and understand the different facets of the business.

What were your key achievements as a Production Manager?

- I introduced a production planning and forecasting technique to better meet customer demands

- I developed a business case and won investment for a brand new layout of the electro-mechanical build area as this was terribly old and underinvested in. I wanted to make improvements in efficiency, multi-skill the team give them an environment to be proud of.

- I installed CNC machinery in our sheet metal department this increased efficiency dramatically and costs could be better controlled.

- I set up a Machine Shop from scratch, we started to make our own parts in-house which led to a reduction in part costs, improved lead times, this created more jobs and greater control over quality.

What challenges did you face?

Taking on the role of Production Manager was definitely a steep learning curve. I found the job very satisfying and fulfilling when I looked back on how modern and efficient the facility had become.

In 2007 I took on the role of Engineering Director where I also managed the design team. Bringing together Designers and the Production Team was tough as each had very different views but the rewards were high when they started to collaborate. Becoming a Director was a significant career milestone for me, to be part of a close-knit team, helping to steer the business and create its growth plans.

In 2010, I ran an 18 month project with the British Design Council to put design at the centre of the business strategies. It was an amazing experience and the whole management team played an integral role. From this work, the company was rebranded and refocused doubling its turnover in the following six years.

In 2014, the business changed hands from a family owned business to be owned by Battery Ventures (now BV), a global investment company that aims to acquire the most prominent companies in their own field.

What has kept you at James Heal for 25 years?

James Heal has never stayed the same and it is constantly changing and evolving. I am passionate about learning and doing new things and I have been able to do both through the course of my career.

Also my relationships with the people here, at all levels, have been very rewarding. hey are fantastic and have a strong desire to do great things and do things right.

The group that owns James Heal is Physical Properties Testers Group and when the company restructured, I was promoted to Director of Operations and Innovation, and Site Manager.

My roles have continually grown and developed. In 2022, as I reached 25 years with James Heal and we celebrated the company's 150th anniversary, I was promoted to Managing Director, PPT Group UK, taking on responsibility for James Heal's fellow PPT Group UK company Mecmesin in Slinfold, West Sussex. In January 2023 I was promoted to Operations Director for the PPT Group, with responsibility for manufacturing across the group, including our latest acquisition Lansmont. A very exciting role!

Subsequently in January 2024, Neil was promoted to Group Managing Director with responsibility for all four PPT Group brands.

What is your career highlight?

One big moment for me was at ITMA 2011 in Barcelona when we launched a new product signature and brand, the reception was tremendous. This was my first undertaking at creating a design language and implementing user-centred design as before, we had approached design from the perspective of an engineering solution. Today, the James Heal brand and product language is very strong and identifiable.

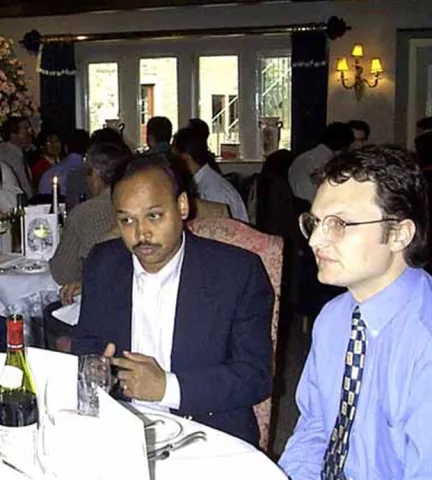

Of course reaching the milestone of 25 years, and at the fabulous party where our staff, agents and partners celebrated the 150th anniversary of James Heal, being presented with a gift, along with other long-standing members of our team, was a very memorable moment.

What does the future hold for James Heal?

James Heal is a company that is constantly improving and there are many things for us to look forward to. We are continuously working on new exciting strategies to improve our offering to new and existing customers. Performance Testing is one significant growth area we are continuing to invest in, as well as developments in some of our core range.

Over the past few years we have developed a range of new instruments that test technical textiles as performance wear is a market that has seen dramatic growth in a wide range of market sectors, from fashion and sportswear to protective work wear. Our Performance Range comprises of six instruments that are specifically designed with testing of technical textiles in mind, the latest two being launched at the end of 2021.

At James Heal, innovation is not just for designers and engineers, it's for all aspects of our business. I see it as a key role of mine to encourage and support everyone in generating new ideas and improving everything we do.

What do you like to do outside of work?

I like to spend a lot of my weekends taking long country walks with my wife and dogs, taking in the scenery and visiting rural pubs for lunch.

My family plays a huge part of my life outside of work. My eldest daughter is at University in Newcastle studying Fashion Design, my son is doing an engineering apprenticeship at James Heal, and my youngest daughter at York University studying Professional Policing.