As part of our 'Essentials' series, we explore the core areas of textile testing and feature the instruments, test materials, and test methods within them, sharing our expertise and advice for best practices to maximise your testing efficiency. In this article, we explain how to use Blue Wool Standards, for accurate and repeatable results.

Blue Wool Standards: Purpose

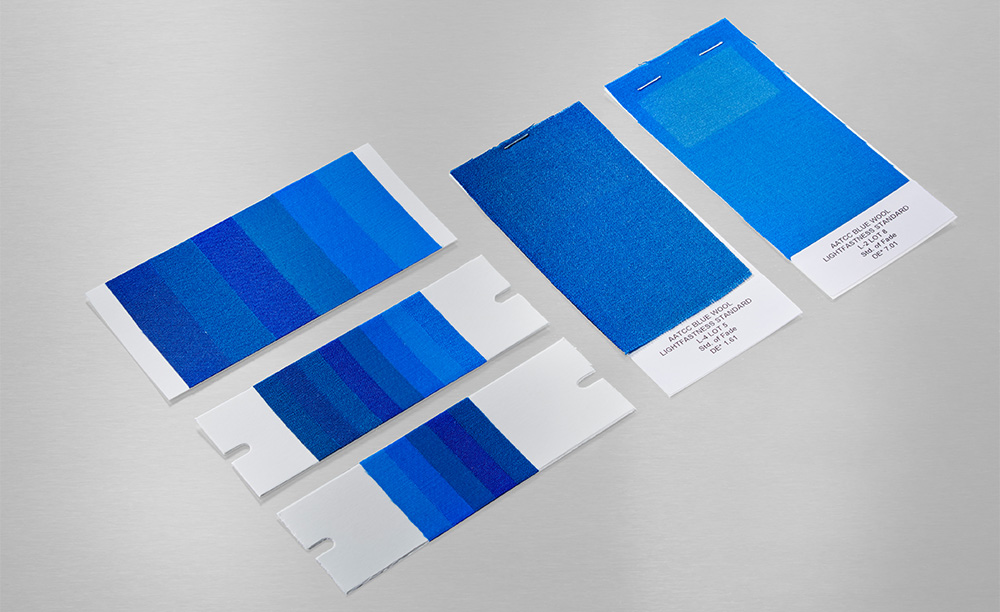

Blue Wools are used for light fastness and weathering testing, to measure and calibrate the permanence of coloured materials, and have been used for many years to indicate the end of test exposure and for grading purposes. Testing a material's reaction to light and moisture is one of the most important, yet traditionally difficult, areas of colour fastness testing, and it's an area we receive many support requests for, from our customers.

Blue Wool Standards: Your questions answered

Below, we highlight some of the most common questions and challenges with using Blue Wools:

What is the fading time for ISO & AATCC Blue Wools?

There are two types of Blue Wool References: 'ISO' and 'AATCC', and we're often asked about Fading Time for both types. This is an important question because there are eight Blue Wool Standard fabrics (referenced 1-8) which have known, yet varied, resistance to light fading - each has approximately twice as resistant to light fading as the preceding fabric. The Blue Wool Standards range from 1-8, starting with number 1 which fade quickly, through to number 8 which has a good resistance to fading and fades much slower. During light fastness testing, the samples are exposed to an intense artificial light generated by a Xenon arc lamp, which goes through a series of filters to ensure that its spectrum closely matches that of natural daylight. whilst the humidity and temperature of the test atmosphere are controlled. Then, a small sample of material, together with the Blue Wool Standards are concurrently exposed to the high intensity light. Following this, the two exposure times are used to calculate if fading has progressed steadily, or at a different rate from the longer-term exposure.

ISO Blue Wools

The ISO blue wools are each dyed with a different dye giving rise to a light fastness scale which is an approximate geometric progression, ranging from 1 to 8. The full range of ISO blue references is currently available. The typical conditions for ISO 105-B02 are:

- 42 W/m2 (300 - 400 nm)*

- 50°C BST

- 40% effective humidity (use red azoic fabric to determine).

*(The SolarSens used with TruFade has one light sensor, referred to as the 300 - 400 nanometre broadband sensor).

ISO Blue Wools Fading Times

- BW1 fades to grey scale 4 in approx. 6 hours

- BW4 fades to grey scale 4 in approx. 48 hours

- BW5 fades to grey scale 4 in approx. 80 hours

Some of the ISO methods use a 'first break' and a 'second break'. If the second break is required then fading is continued further until greyscale 3 is achieved (this takes the same time again as it did to get to greyscale 4).

AATCC Blue Wools

The AATCC blue wools are produced from two dyed wool batches: one batch has a very low light fastness dye, and the other a very high light fastness. The two batches are then blended together in different proportions to give the range L2 to L9. Currently, due to problems sourcing the dyestuff in the wider supply chain for health and safety reasons, the L9 (high light fastness) cannot be produced. As a result, only L2 is currently available. The typical conditions for AATCC 16.3 are:

- 48 W/m2 (300 - 400nm)

- 63°C BPT

- 30% relative humidity.

AATCC Blue Wools Fading Times

L2 fades to grey scale 2-3 in 20 AFU (American Fading Units), which is approximately 20 ± 2 hours under the above conditions.

How many hours of daylight exposure does each Blue Wool Reference correlate with?

Blue Wool References are not correlated against actual daylight exposure. This is because real conditions vary. It is not just the light that needs taking into consideration, but the temperature and humidity also. As an example, we can say that if the irradiance is controlled at 42W/m² (300 - 400nm):

- Blue Wool 5 will fade to a grey scale 4 in approximately 80 hours

- Blue Wool 6 will fade to a grey scale 4 in approximately 160 hours

Blue Wool References are designed to fade in a geometric progression. Each successive reference taking twice as long to fade to the same grade as its predecessor, e.g. a fabric with a colour fastness to light of 6 is twice as good as a fabric which has colour fastness to light of 5.'

How can I be assured that Blue Wools from James Heal perform correctly?

James Heal Blue Wools are made in Germany and originate from DEK - The German Colour Fastness Commission. DEK hold the global master standards. Every batch of Blue Wools 1-7 is rigorously tested for conformance against ISO 105 - B08. The tests are:

- Instrumented assessment of evenness of the dye

- Instrumented and visual assessment of the fading characteristics

Blue Wool 8 is not suitable to be tested in this way as the time taken to fade to a grade 3 and 4 would be too great and not time effective. A more efficient method for Blue Wool 8 is currently being devised.

What are the Blue Wool Standards for Storage and what is the Shelf Life?

If properly stored, these test materials can be used for at least two years in an unrestricted standard-compliant manner for determining and evaluating colour fastness to light and weathering. What does 'Proper storage' mean? To ensure your blue wools are correctly stored for optimum performance, you must aim to store them:

- In the original packaging and in a dry, dark place

- Protected from direct sunlight and as cool as possible

- In no event at a temperature above 25°C

- In an environment free of chemicals and air pollutants

With the blue wool light fastness standards, it is particularly important that measures are consistently taken to protect them from unintentional exposure to daylight and/or artificial light. And, when not in use, these should therefore always be stored between the black sun protection boards and, if possible, any exposure to light that is not related to the actual test should be avoided.'

Final Thoughts

Subjectivity and variability of results is something all testing professionals should be mindful of when using blue wools. A significant challenge which presents itself with blue wool reference scale (and also the grey scale) is that it is a subjective test - e.g. it depends on an experienced technician comparing changes in test samples versus the reference swatches, which leads some variability in results. Our advice is to start by assessing samples once during the test, and again at the end, to improve reliability of results. To read more about our Blue Wool and our test materials range please click here. Alternatively, get in touch with any queries you may have.